Medical gas alarms and zone valve boxes are essential components in any healthcare facility that uses medical gases such as oxygen, nitrogen, and nitrous oxide. These gases are critical to patient care, but they can also pose serious safety risks if not properly monitored and controlled.

Medical gas alarms are designed to alert healthcare staff to potential leaks or other issues with the gas delivery system. These alarms can detect low oxygen levels, high levels of other gases, and pressure drops in the system. They provide an audible and visual warning to staff, allowing them to take action quickly to address the problem.

Zone valve boxes are another important component in medical gas systems. They are used to control the flow of gases to specific areas of the facility, such as operating rooms, patient rooms, and laboratories. Each zone valve box is connected to a specific area and can be closed off in the event of a leak or other issue. This helps to contain any potential hazards and prevent them from spreading throughout the facility.

Pattons Medical is committed to providing the best medical and laboratory gas solutions in the market. Our products meet and exceed NFPA 99 and CSA Standards and are UL approved.

VALVES

Source valves are required at the source equipment to isolate the system from the rest of the hospital. Mainline valves are required on the top line if the source equipment is located outside the facility. This would be placed on the line as it immediately enters the building. Riser valves are required on the riser adjacent to the main line in service, or floor valves are required off the branch of the riser.

ZONE VALVE BOXES

A zone valve is a shutoff valve for the zone or area it serves, with its fundamental purpose being fire control. All medical gas outlets must be covered by a zone valve box on the same floor they serve. A zone valve box should not be located in a room with the outlet it controls, and a wall should intervene between the zone valve box and the outlets it controls. If you’re standing at a zone valve box, you should not have an outlet it controls in your line of sight. It needs to be available to the floor staff. A removable cover must be visible and accessible at all times and readily operable in a standing position. For that reason, the code states that it should not be hidden behind an open door or in a closed locked room area.

A zone valve box should be placed in a logical exit corridor. If there is a fire, the staff should be able to turn the valve off on their way out of the building. The placement will need proper wall space because it will include the zone valve box and the piping associated with pipe in and out from it. Pattons Medical can help your properly calculate the wall space needed and where it would be a good place to put a zone valve box.

A zone valve box needs to be labeled to include which area it serves. They should be piped left to right, and they cannot be placed in series. You should never have a zone valve box downstream of another zone valve box. Any critical car or live support anesthetizing location needs its own zone valve. That being said, an ICU may have one shared zone valve box that has to do with classifying the ICU area has a single occupancy. They have a dedicated nursing staff and nurse’s station, all of the patients are receiving a similar level of care. Patient room areas should be broken up with what makes the most sense to your facility’s layout. The code does not dictate how many rooms can fall under one zone valve box.

Pattons Medical zone valve boxes can be figured to hold up anywhere from one to seven zone valve boxes, which includes the tube extensions. They consist of a pullout, removable, opaque window and have larger color-coded ID labels. Adjustable steel brackets are provided for mounting and two-inch single-zone valves are available in a four-inch depth box.

ALARMS

There are three types of medical gas alarms : a local alarm, a master alarm panel (MAP), and an area alarm panel (AAP).

LOCAL ALARMS

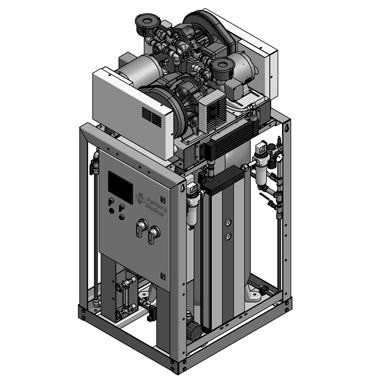

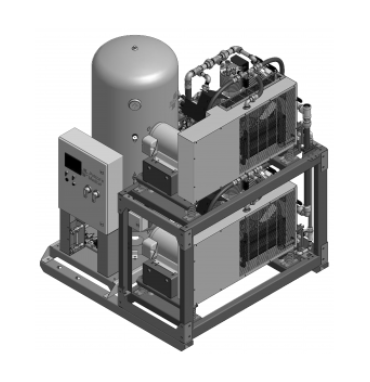

Local alarms are local to the source equipment. On the left of the control panel, there is a typical HMI System Health panel that’s on the control panel for all our air and vac systems. On the right of the typical panel for our manifolds, provide an audible and visual alarm.

MASTER ALARMS

Master alarms only monitor the source equipment. The wires run parallel from each of the source equipment, control panels, and mainline switches back to two primary MAPs for a category one facility. If a facility would like a third master alarm panel, it is doable and can be slaved off of one of the primary master alarm panels, but the two primaries need to run in parallel. One needs to sit in the office of the person who is responsible for the medical gas equipment. In a full-service hospital, that would be a maintenance or engineering department. The other needs to sit in a 24-hour location, which is wherever staff will be present when the facility is open.

Discussing wiring from the source equipment and the mainline switches, the mainline high-low pressure switches should be installed immediately downstream, or on the patient side of the source valve. Note that if a mainline valve is required, the pressure switch engages should be installed downstream or on the patient side of the mainline valve as it comes into the building.

Gauges are required to be adjacent to pressure switches. Pattons Medical does a mainline pressure switch engage which only requires one paper off the mainline. All alarm wiring should be a minimum of 22 gauge, and power should be from the life safety branch of the emergency electrical system.

All Pattons Medical alarms are ethernet capable. Not only does that provide the best end-user texts and emails when an alarm goes off, but it also provides a conduit to talk to the BMS, and you would just need to specify that you want ethernet capability. For the master alarm panel points for a typical scroll air compressor system, you’d have five points. In a typical claw vacuum system, you’d have two points and for a high-pressure manifold, you’d have three points. That is a total of ten points, which is the minimum required at the master alarm.

AREA ALARMS

An area alarm monitors the pressure or vacuum in the area of the zone it serves. For pressure, it will alarm 20% high or low from the main pressure. For vacuum, it will alarm at low vacuum level of 12 inches of mercury. These should be located in the area of the person responsible. For example, a narcs station, they will need to be labeled for the area served and sensors should be located to permit access for testing.

An area alarm panel does not communicate or talk to a master alarm panel. Master alarms monitor the source equipment; area alarms monitor the area they serve. All of Pattons Medical alarms are ethernet capable, but we don’t need to have that capability of area alarms so much. It tends to add-up price-wise if you’re making your area alarms ethernet capable – but it is doable and available.

An area alarm panel is required in any anesthetizing location where moderate or deep sedation or general anesthesia is being performed and within any critical care areas. Any zone or area can have an alarm panel. For example, when you’re designing a tower, with the top four floors as patient wings, it is good practice to have an area alarm panel per floor.

Typically, the sensor is placed on the patient side of the zone valve box to monitor any pressure differentials for that area. Code does not allow for one area alarm panel for an operation room (OR) or anesthetizing suite, that sensor would be placed of the source side of its own valve box. You can put one area alarm per one valve box, but when you are designing a full-service facility, that can add up in price quickly. If you have any questions about where the sensor should be placed, do not hesitate to reach out to Pattons Medical.

SENSORS

Regardless of where the sensor is placed to monitor the pressure or vacuum, where are they physically located? They can be located in the alarm panel itself, which would be considered local. Or, they can be placed on the ceiling and the pipe, which would be considered remote. We can place them in the zone valve box and wire them back to the panel, which also can be called sensor provision.

Sensor provision is good because it allows access to these sensors for testing and annual verifications. Pattons Medical can help with this to show you where they should be an where it is, and is not necessary to have one.

COMBO ALARMS

Something that has come out recently is called a zone valve box and area alarm panel combo (ZVB/AAP combo). Not only are the sensors in the zone valve box, but there are also alarm panels outside on the zone valve box as well. This has a very unique fit for an extremely small facility that might not have a nurses’ station.